Overhead Door OHDI1-NF

OHDI1 - NF

Used as the main door or the intersection between the warehouse and the Dock House.

0.3 (m/s)

15 - 20 days

Road transport

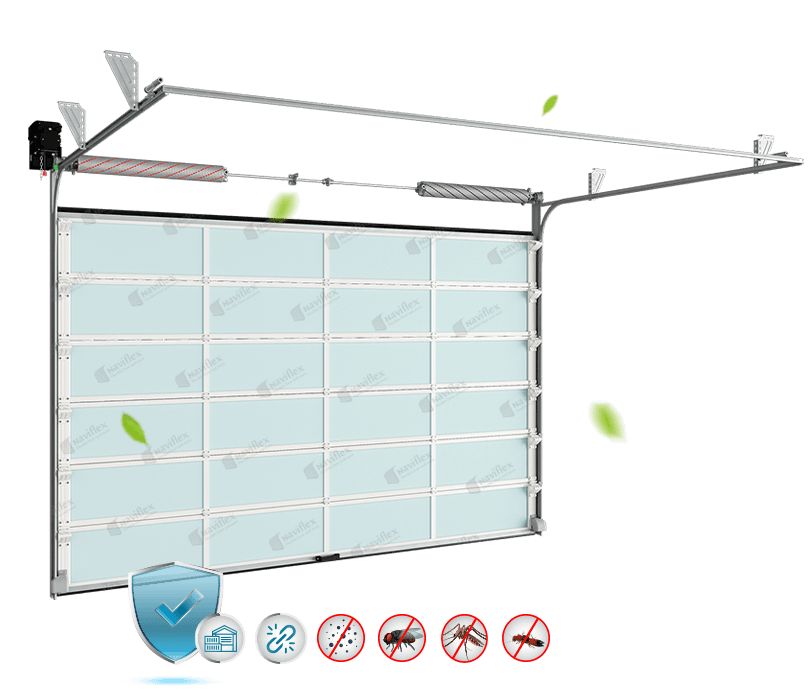

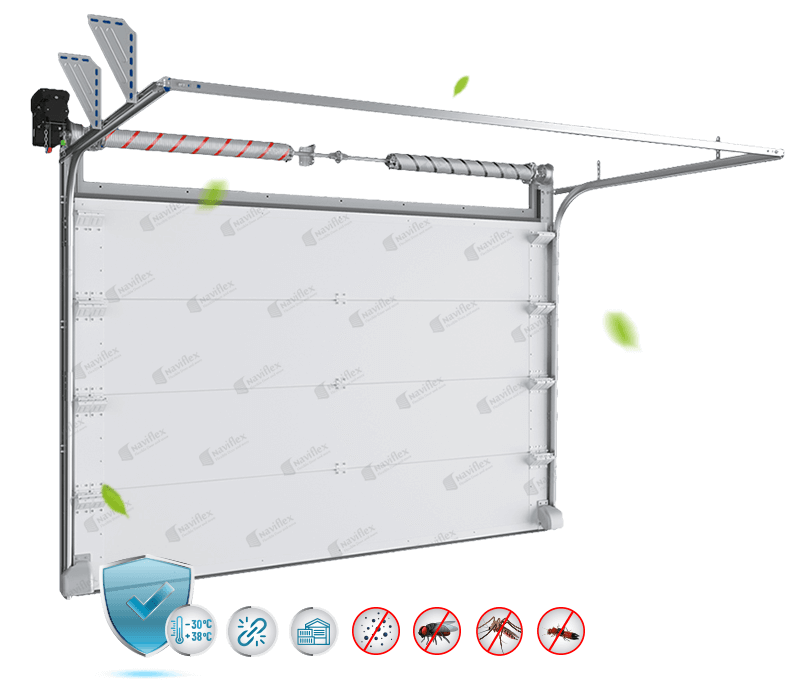

Overhead Door OHDI1-NF is manufactured on request with European quality standards, considered an effective solution to support circulation, wind resistance, and impact resistance.

Overhead door OHDI1-NF is an industrial ceiling sliding door, operating under the mechanism of sliding panels under rails (square, oblique, vertical) with low ceilings, with no need to use rollers. The Overhead door body is assembled by panels on, galvanized steel surface, in the middle of the sandwich (PU) PIR 2 layers with a thickness of 42 (mm), providing good sound insulation, heat insulation, and impact resistance.

ADVANTAGES

- Good wind resistance: Good wind resistance of 10 – 12 (28 m / s – 35 m / s), limiting heat loss and preventing potential risks such as dirt, insects, and food safety…

- Persistent activity: The door frame is made of galvanized steel, which prevents the door from shaking at the highest opening and closing speed.

- Safe device: Airbag obstacle sensing device (closed door facing an obstacle will automatically roll up). Emergency notification system when there is a problem, easy to open by hand if there is a power failure or technical error.

- Easy to use and clean: With the diverse and simple control system, curtains are easy to clean and clean.

- Meet food safety standards: Produced according to European technology standards. Helping the factory to meet the safety standards in production operations: ISO 14000, ISO 45001: 2018, ROHS, HACCP, GMP…

- Modern design, ensure aesthetics.

Specifications

Operations

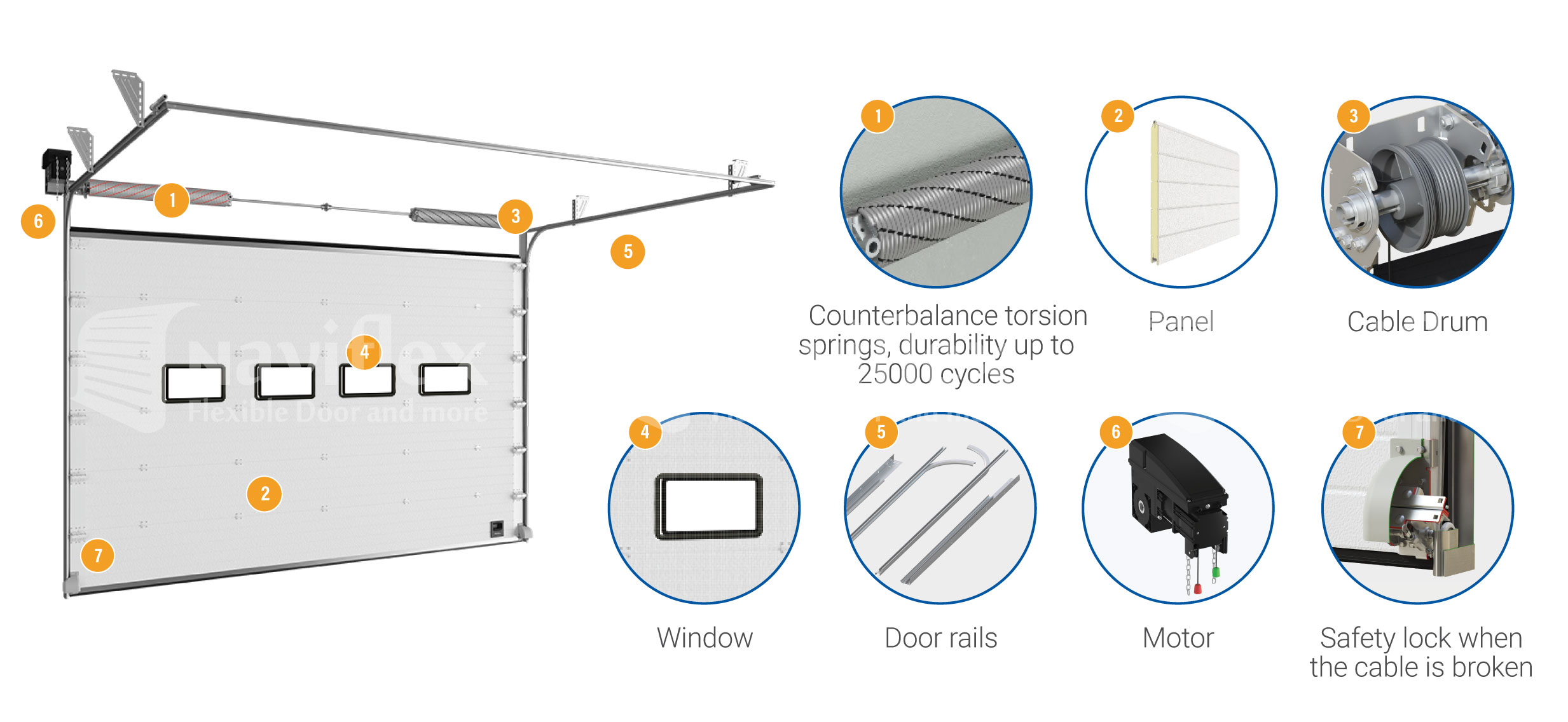

ACCESSORIES

|

Corrugated panel |

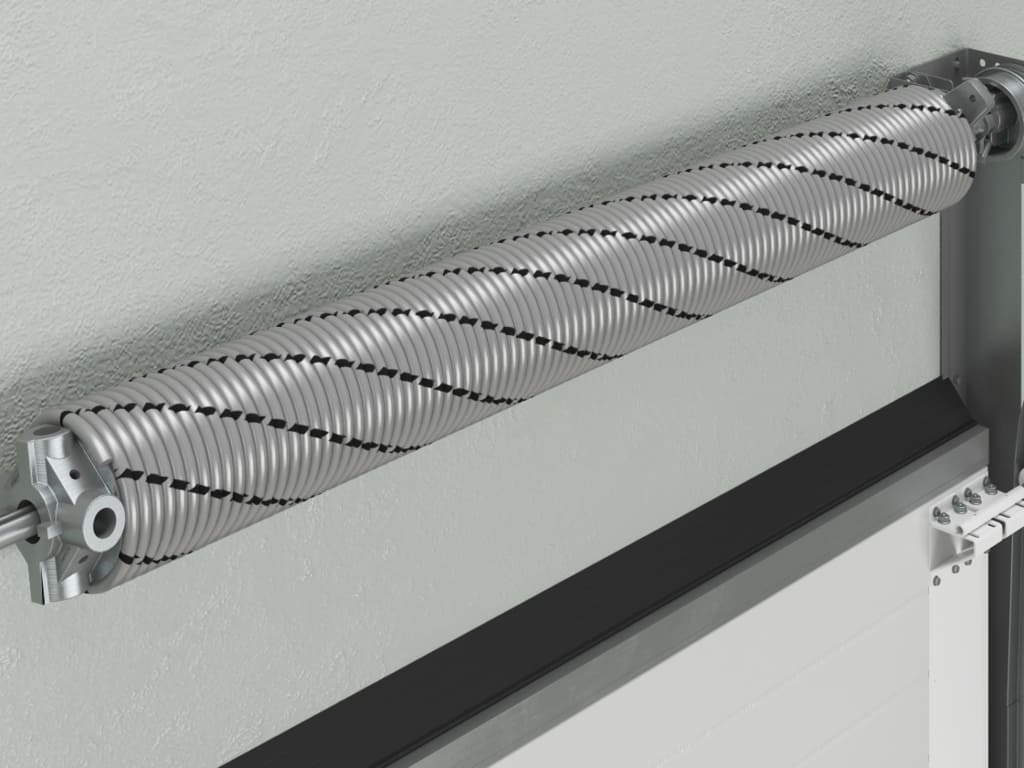

Counterweight torsion springs |

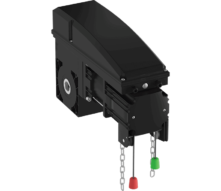

Motor |

|

Door rails |

Cable drum |

Cable |

|

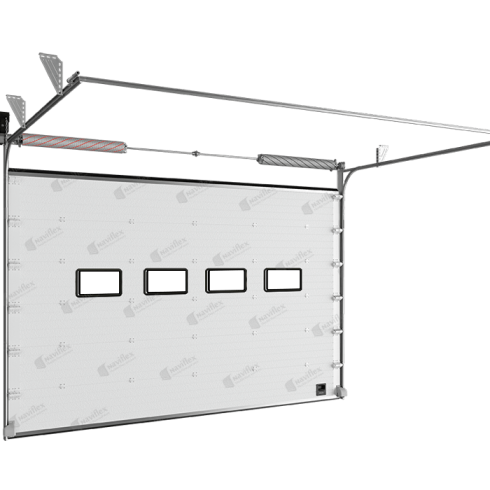

Window |

Safety lock |

The winch set

|

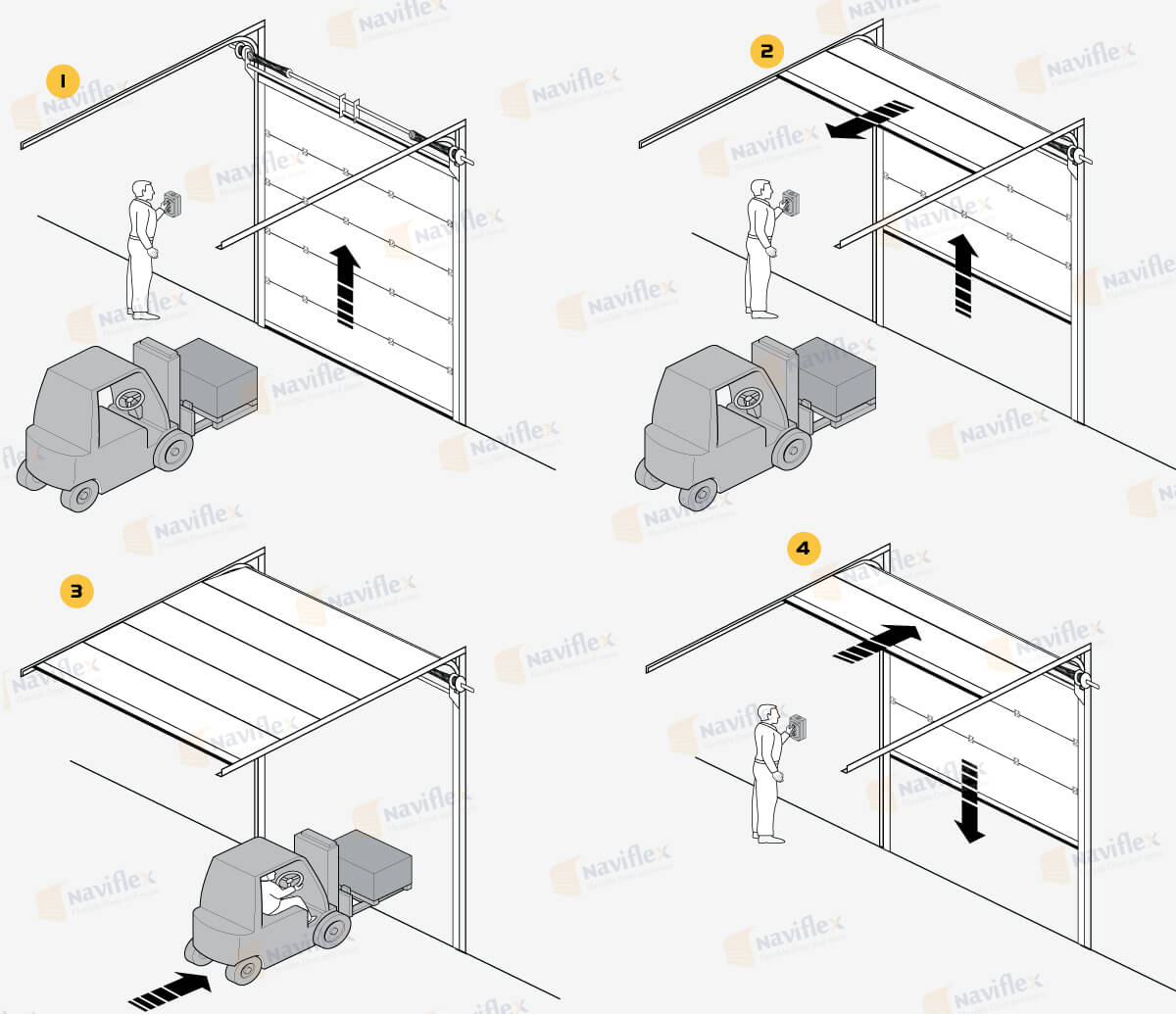

INSTALLATION:

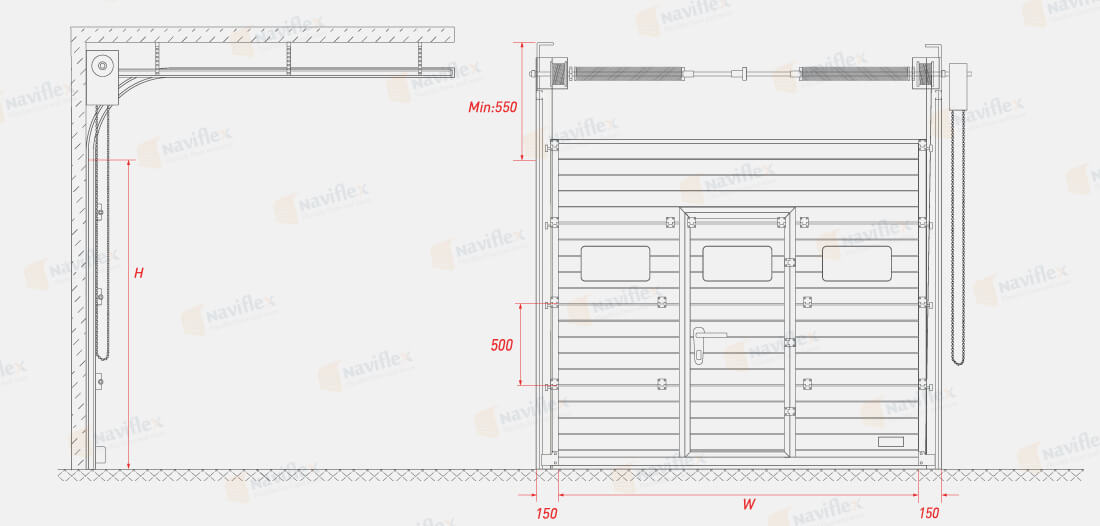

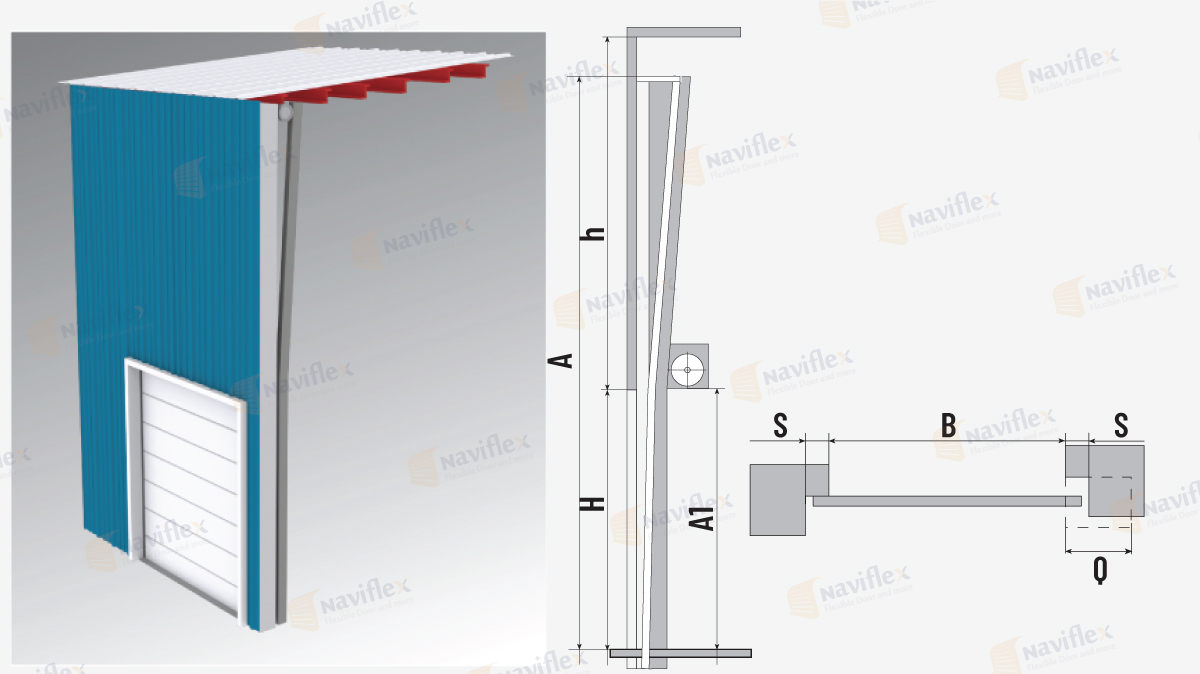

Technical drawing of Overhead Door OHDI1-NF

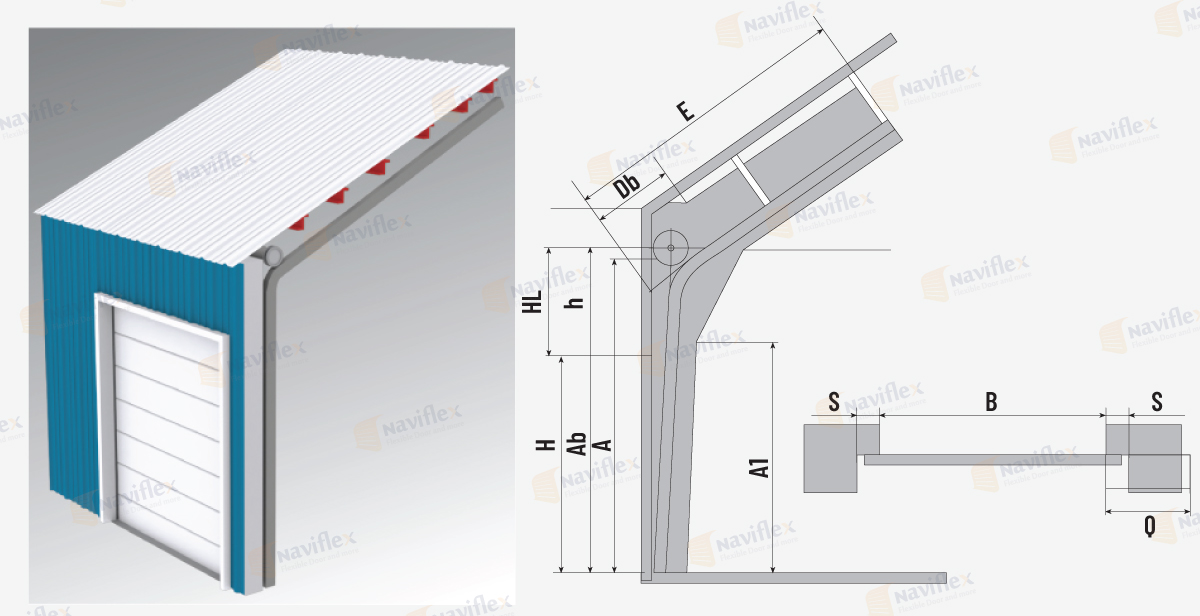

Technical drawing of Overhead Door OHDI1-NF

| H | ≤ 8000 (mm) |

| W | ≤ 8000 (mm) |

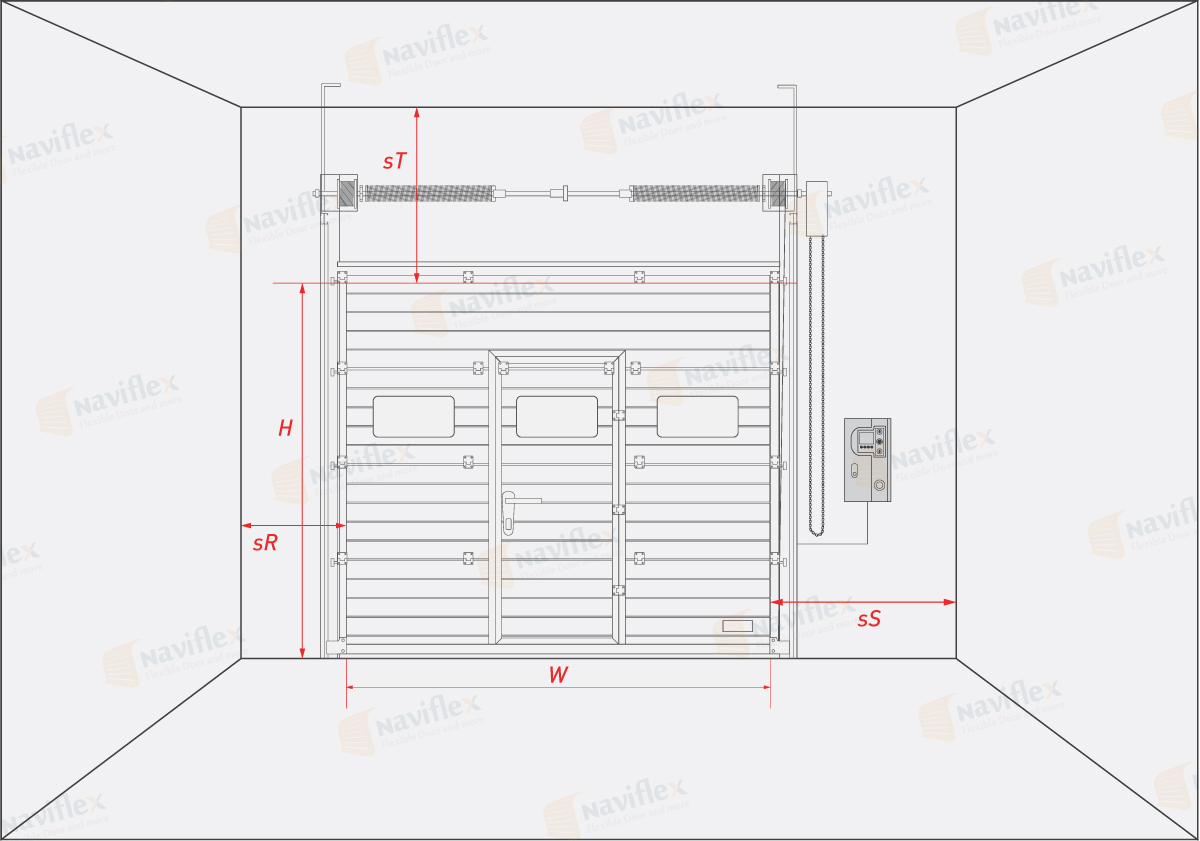

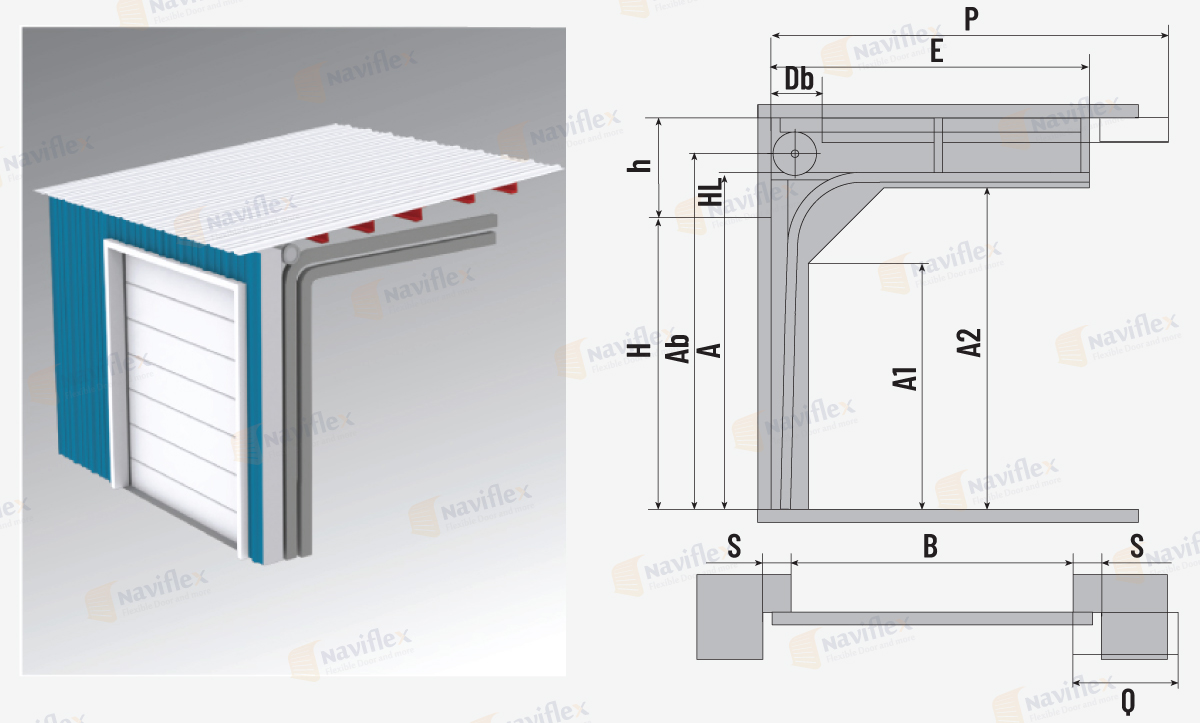

Technical drawing of Overhead Door OHDI1-NF

| H | ≤ 8000 (mm) |

| W | ≤ 8000 (mm) |

| sT: Space waiting for the top of the door. | min: 550 (mm) |

| sS: Space waiting for the door wall on the side with the motor and the electrical cabinet. | min: 350 (mm) |

| sR:Space to wait for door wall without motor and electrical cabinet. | min: 150 (mm) |

Drawing board of vertical sliding rails OHDI1-NF

The vertical rail is a type of door operating vertically, not in a roll, meeting the factors such as insulation, electricity, noise prevention, dust and insects.

Drawing board of slant sliding rails OHDI1-NF

Oblique rails are combined sliding doors, designed according to modern technology, with each door made of pieces with links linked to Palang and propulsion motors.

Drawing board of perpendicular sliding rails OHDI1-NF

Perpendicular rail is a type of perpendicular sliding door, designed with high technology, with absolute safety, outstanding advantages, helping users to be more satisfied with the product.

- H (mm) Clearance height.

- h (mm) Headquarters height.

- B (mm) Clearance width.

- A (mm) Track angle height.

- Ab (mm) Height of shaft and empty.

- A1 (mm) Vertical groove height.

- E (mm) Horizontal groove length.

- Db (mm) Torsion spring operating space.

- S (mm) Clearance of room minimum.

- Q (mm) Axle opening position.

Overhead Door OHDI1-NF has 3 main ways of operation: push button on the controller, magnetic sensor/sensor, and zipper according to European standards, making operation simple, safe, and suitable for many different environments.

Packaging & Delivery

Packing in wooden/cotton/PE film carton.