Sliding cold door CLD02-NF

CLD02 - NF

Usually used in deep negative cold storage to separate inside and outside temperature.

Updating

15 - 20 days

Road transport

Sliding cold door CLD02-NF is manufactured on demand with European quality standards, considered the optimal solution for cold, sound, and electrical insulation.

Sliding cold door CLD02-NF is a type of door that operates on a sturdy sliding rail frame, smoothly opening and closing. With the characteristics of preventing cold steam loss, heat insulation, electricity, and sound insulation effect, without causing noise.

The main material of the door is steel with a PU insulation coating of various thicknesses and the core is made of Polyurethane material that enhances the ability of insulation, electricity, smooth operation, and no noise. The suspension bar is designed with a durable aluminum alloy, with a bright surface for high aesthetics. Specialized doors for frozen warehouses, food preliminary processing facilities, pharmaceutical warehouses, or food preservation storage… ensure to meet safety and quality criteria.

ADVANTAGES

- Good cold keeping: The rubber gasket at the door helps to squeeze the wing frame, and the Polyurethane core increases heat resistance and prevents heat loss.

- Persistent activity: The door body is structured between anodized aluminum and stainless steel, so it is highly water-resistant persistent activity, and undamaged when a strong impact occurs.

- Quick installation: The door is structured simply so it is easy to construct, install or disassemble, quickly repair or replace spare parts and does not take much time.

- Safe when using: The door with a safety lock can be opened from the inside, stainless steel lock and rubber gasket help reduce risk.

- Meet food safety standards: Produced according to European technology standards. Helping the factory to meet the safety standards in production operations: ISO 14000, ISO 45001: 2018, ROHS, HACCP, GMP…

Specifications

Operations

ACCESSORIES

|

Sliding rails |

Insulation panel |

Motor |

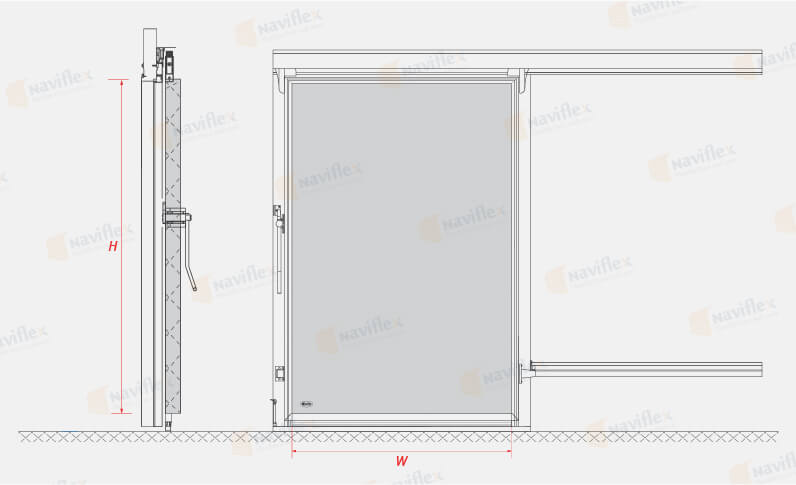

Technical drawing of Sliding Cold Door CLD02-NF

| H: Clearance height | ≤ 3500 (mm) |

| W: Clearance width | ≤ 5000 (mm) |

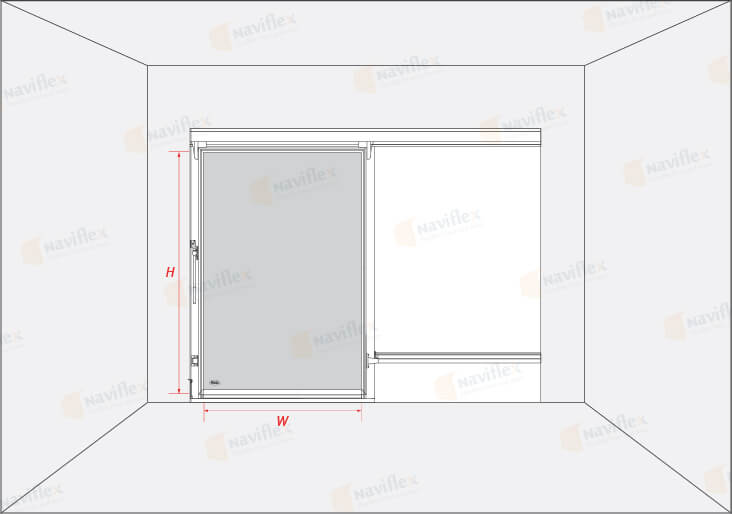

Technical drawing of Sliding Cold Door CLD02-NF

| H: Chiều cao thông thủy | ≤ 3500 (mm) |

| W: Chiều rộng thông thủy | ≤ 5000 (mm) |

Updating……

Packaging & Delivery

Packing in wooden/cotton/PE film carton.